ARMATUREN-TECHNIK is since its foundation in 1995 under pressure. The company from Oberhausen, Germany designes and produces hight pressure valves for power plant applications according to customer specifications. Shut-off valves, control valves, steam conditioning valves and turbine bypass stations are made of forged steel which endure in high pressure and high temperature environments. “We guarantee a minimum life of 25 years,” explains Manfred Leufgen. “More than twice as much as our competitors. The warranty is twice as long compared to many of our competitors.”

Technically two generations ahead

The CEO of ARMATREN-TECHNIK considers Germany as a leader in power plant construction. “We are technically at least two generations ahead”, Manfred Leufgen is safe for his company. Accordingly the reputation abroad is correspondingly great. The Oberhauseners build their valves in power plants in the Middle East, South America, India, Korea, China and Japan.

In doing so, the foreign customers attach great importance to the fact that the quality is “Made in North Rhine-Westphalia”, but still domestic companies are involved. “We can ensure this local share,” says Manfred Leufgen. For example, the partner companies build the housings of the valves under the guidance of employees of the ARMATUREN-TECHNIK. The know-how remains in Oberhausen. In addition to such project-based partnerships, the specialist for high-pressure valves maintains long-term partnerships.

ARMATUREN-TECHNIK

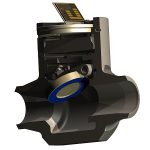

Based in Oberhausen, Germany, ARMATUREN-TECHNIK is an innovative and “engineering-centered” manufacturer of high pressure valves. The company was founded in 1995 and currently employs 21 people. ARMATUREN-TECHNIK today has cooperation partners and customers across the entire globe. The product portfolio consists of a broad array of standard and tailor-made valves and includes turbine regulation stations, control valves, steam valves, bypass valves, gate valves and check valves.

afric-Invest

afric-Invest